High-quality and reliable overcurrent protection solutions for the entire production cycle

E-T-A offers you high-quality and reliable overcurrent protection solutions for the entire production cycle – from the press shop over bodywork to final assembly.

Our product range with listed quality products covers both standard applications as well as intelligent system solutions with comprehensive diagnostic functions.

We shall be pleased to assist you in planning flexible and favourably priced protection solutions for your complex transport management systems, assembly lines and test equipment.

-

Press Shop

Press Shop

Press Shop

Press Shop

In press shops, the automation degree is very high. The components must withstand extreme shocks and vibrations. Unrivalled quality and permanent availability are important to avoid failures and related financial losses.

Applikation 1 Produkte

-

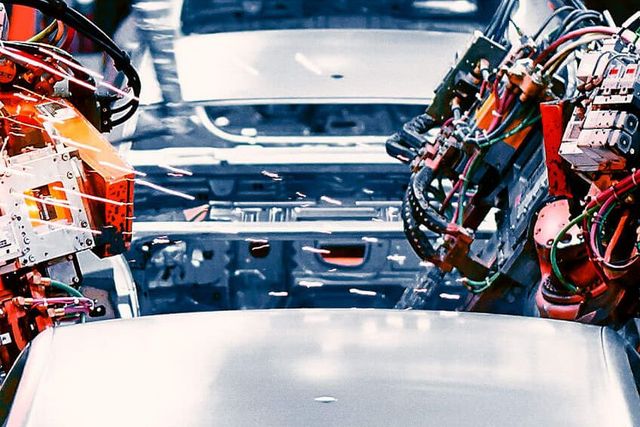

Body shell / bodywork

Body shell / bodywork

Body shell / bodywork

Body Shell / Bodywork

Reliability and quality are of major importance in the sector of frame-and-body construction. Our products offer group signalisation, single signalisation or communication via ProfiNet minimising downtimes - you can choose from all options.

Applikation 1 Produkte

-

Materials handling technology

Materials handling technology

Materials handling technology

Materials Handling

A common element of all work steps is the materials handling technology. Electric overhead conveyors, floor conveyor technology or driverless transport systems move body and vehicle parts between individual systems and functions.

-

Paint shop

Paint shop

Paint shop

Paint Shop

Reliability of the components is also very important in the paint shop. The cars are sprayed with different colours one after the other while on the paint-spray line. Downtimes in automobile paint lines have to be prevented without fail, occurring faults must be detected and remedied as quickly as possible.

-

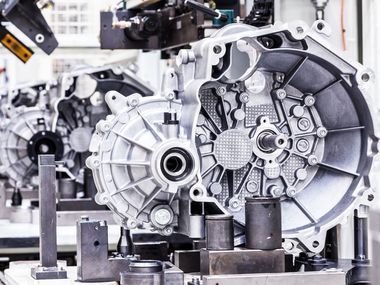

Powertrain

Powertrain

Powertrain

Powertrain

Powertrain production is characterised by machine tools and assembly lines. Protection solutions need to be compact, flexible and cost-effective. Diagnosis via IO link allows complete transparency of the DC 24 V power supply and is a part of predictive maintenance.

-

Assembly

Assembly

Assembly

Assembly

Final assembly holds the highlight of car production: The marriage!

Body and powertrain meet. DC 24 V protection and power distribution are of the utmost importance both at the assembly line and in the test equipment. Many sensors, actuators and the control unit need to be optimally protected to ensure smooth operation of the process.

Applikation 1 Produkte

Unrivalled system availability

The E-T-A portfolio consisting of standard components, intelligent circuit protectors and entire system solutions ensures reduced downtimes of your machinery and equipment. Our products are resistant against harsh conditions in production processes such as dirt and vibration. Comprehensive diagnostic functions via IO link and Industrial Ethernet provide you with the required transparency of machine status and production status and they ensure predictive maintenance.

Listed components and systems

Our modular components feature a flexible and space-saving design and allow plant operators quick and precise trouble-shooting. Reliable system solutions are tailor-made to the requirements of the automotive industry. Therefore our products are listed in the OEMs’ lists of preferred suppliers.

More info (German website):

E-T-A forum for automobile production

Global support for a high availability

Around the globe, E-T-A has four production facilities, ten subsidiaries and a number of representatives in more than 60 countries and is your first contact for reliable overcurrent protection solutions. Together, we plan a protection solution that is customised to your requirements – all over the world.

Downloads

Brochures and flyers about automotive manufacturing

-

General brochures

General brochures

- Product flyer